Introduction

One of the most effective ways of detecting potential machine failures prior to them becoming too expensive and serious, is by measuring wear metals in lubricating and engine oils. Often, these elements can also help to identify the failing component. Besides wear elements, measured elements include additive elements, and elements from fuel and external contaminants. Some elements can have multiple sources.

Spectroscopy

Spectrometry is the main technique used for detection of wear, and its severity. Since every element is characterized by a unique atomic structure, the addition of energy causes each element to release light of specific wavelength (or colour). The difference between the spectral lines of different elements helps to distinguish them from each other. The intensity of the light emitted varies in proportion to the amount of element that exists in the sample, enabling the determination of its concentration.

There are different methods of adding the energy to the elements, such as Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma Spectroscopy (ICP), Rotating Disc Electrode Spectroscopy (RDE), X-Ray Florescence Spectroscopy (XRF), etc. Each has its strengths & weaknesses.

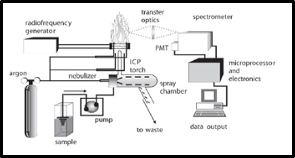

Fig. 1 INDUCTIVELY COUPLED PLASMA SPECTROSCOPY (Ref 2)

ICP is the most used method. It is accurate and gives high repeatability. But it requires trained technicians and lots of clean argon gas, automation, and maintenance. It is well suited for high-throughput labs. A stream of argon gas is ionized at high temperature, a small amount of diluted sample fluid is injected into the plasma through a nebuliser and the spectral emission is recorded, measured, and analysed. However, particles larger than 5 – 7 microns are not well detected by this method as they are not fully vaporised in the plasma due to mass effects and so wear element concentration can be underestimated in cases of high wear. Additional processes (e.g., acid digestion) may be required for such samples.

It must be noted that depending on the type of test equipment and sample preparation, the results obtained can be quite different. When comparing or plotting results for trend analysis, ideally one should be comparing data from the same laboratory, the same apparatus, and the same method. Also, the accuracy and detection limits of the methods should be considered. Low values (below 5 ppm) should be interpreted with caution.

Various ASTM standards for spectroscopy cover different sets of elements & number of elements. LUKOIL Marine carries out elemental analysis as per ASTM D5185-18

A TO Z OF SPECTROCHEMICAL ELEMENTS

|

DETECTED ELEMENT

|

POSSIBLE SOURCES

|

||||

|

ELEMENT

|

LUBRICANT

|

CONTAMINANT

|

ENGINE

|

HYD SYSTEM

|

OTHERS

|

|

Aluminum (Al)

|

Grease thickener

|

Cat-Fines,

Dirt & Dust

|

Pistons, Bearings,

Bushings, Shims

Head Block,

Cylinder Block,

|

Pump/Motor housings,

Cylinder glands

|

Air Comp Pistons, Blowers, Rotors, Thrust bearings,

Turbocharger bearings, Impellers,

Clutches, Coolers

|

|

Antimony (Sb)

|

Grease additive

|

|

Bearings (overlay)

|

|

|

|

Barium (Ba)

|

Additive,

Grease Thickener

|

|

|

|

|

|

Boron (B)

|

Limited EP Additive,

Grease

|

Water inhibitor, Coolant (borate)

|

|

|

|

|

Cadmium (Cd)

|

|

|

Bearings

|

|

Plating’s

|

|

Calcium (Ca)

|

Detergent Additive,

Grease Thickener

|

“Hard” Water,

Dirt,

|

|

|

Airborne contaminant

|

|

Chlorine (Cl)

|

AW & EP Additive

|

Sea Water

|

|

|

Sea water

|

|

Chromium (Cr)

|

|

Chromate corrosion inhibitor from coolants

|

Cylinder liners,

Rings, Crankshafts

Some Roller Bearings,

Exhaust Valves

|

Bearings cages,

shafts

|

Bearings, Valve Spools,

Some plating materials

|

|

Cobalt (Co)

|

|

|

Some Roller Bearings

|

Some Bearings

|

Turbine components

|

|

Copper (Cu)

|

|

Anti-seize compound

|

Bearings, Bushings (wrist pins),

Oil Cooler, Radiators, Camshafts, Clutches,

Valve guides,

|

Pump pistons & thrust plates,

Coolers,

Cylinder glands

|

Heat Exchangers,

Bearings, Bushings, thrust washers, Brass (in conjunction

with Zn), Bronze (in conjunction with Tin), Discs, Wear plates, Sealants

& Gaskets

|

|

Indium (In)

|

|

|

Bearing overlay

|

|

Solder,

|

|

Iron (Fe)

|

|

Rust

|

Cylinders, Blocks, Gears, Crankshaft, Rings, Camshaft,

Cams, Valve train Bearings, umps,

|

Pumps/Motors housings, vanes, gears, pistons, Rods,

Valves

|

Gears, Shafts, Housings, Fasteners, Crankshafts,

Shafts, Rods, Rings, Bearings

Thrust washers,

|

|

Lead (Pb)

|

Additive

|

Paint

|

Bearings, Bushings, overlay,

|

Seals

|

Solder, Anti-seize, Petrol/gasoline additive

|

|

Magnesium (Mg)

|

Detergent Additive

|

Sea water,

|

Component Housing, Some Al alloy parts

|

|

Aluminum alloy parts

|

|

Manganese (Mn)

|

Additive

|

|

Valves, Blowers, Exhaust & intake Valves

|

|

Alloy parts(unleaded) Petrol/Gasoline additive

|

|

Molybdenum (Mo)

|

AW Additives,

Friction modifiers

|

|

Piston Ring overlay, liners

|

|

Anti-Cavitation inhibitor

|

|

Nickel (Ni)

|

|

Crude oil constituent carried over in Residual Fuels

|

Bearing metals, valve stems/guides,

ring inserts on pistons, turbo charger blades,

|

|

Stainless Steel components,

High Strength Steels, Gears

|

|

Phosphorus (P)

|

AW & EP Additives

|

Coolants

|

|

|

pH buffer

|

|

Potassium (K)

|

|

Coolants,

|

|

|

pH buffer

|

|

Silicon (Si)

|

Anti-foam Additive

|

Cat-fines, Sand, Airborne dust, Anti-freeze

|

|

Seals

|

Transmission Disc Linings

|

|

Silver (Ag)

|

|

|

Some Engine Bearings (e.g., EMD engines)

|

|

Bearing Cages, Solder

|

|

Sodium (Na)

|

Additives,

Grease Thickener

|

Sea water,

Coolant, Dirt, Crude oil constituent carried over in

Residual Fuels

|

|

|

Anti-Freeze, Sea water contamination in fuel

|

|

Sulphur (S)

|

AW & EP Additive

|

Crude oil constituent carried over in Fuel

|

|

|

|

|

Tin (Sn)

|

|

|

Piston overlay, Rings

Bearing overlay,

Bushing’s wrist & pins,

|

Seals

|

Solders,

Bearing overlay, Bronze & White metal alloy component

|

|

Titanium (Ti)

|

|

Paint

|

Springs

|

|

(Gas) Turbine components,

|

|

Vanadium (V)

|

|

Crude oil constituent carried over in Residual Fuels

|

Turbine impeller blades, Valves,

|

|

Turbine components,

Surface coatings

|

|

Zinc (Zn)

|

AW additive, Corr. & Oxid. inhibitors

|

|

Component of brass alloys

|

|

Galvanized metals & plating’s,

Component of brass alloys

|

Particulate Quantifier (PQ)

PQ Index is the measurement of the total ferro-magnetic metal content in oil. Particle Quantifier exposes a lubricant sample to a magnetic field and the presence of ferrous metals creates a distortion in the magnetic field. If the PQ index is high, the ferro-magnetic metal content in the sample is high and abnormal (Abrasive/Adhesive) wear is likely taking place.

Fig 2. Particulate Quantifier (Ref 3)

Generally, wear under aggressive tribological conditions such as abrasion & adhesion tends towards producing wear debris over a wide range of sizes. As a result, spectroscopy, which only captures data from particles typically less than 5-7 μm in size, may tend to plateau or even reduce over time, while PQ value is rising.

Thus, PQ is a good adjunct to spectrometry. Trends of PQ and Fe (measured by spectrometry) allows better interpretation of the kind and severity of the wear taking place. LUKOIL carries out PQ test on most samples where spectrometry is carried out.

A version of this article first appeared in the the SEP 2021, Vol. XV; Issue. X. of Marine Engineers Review

References:

- Used Engine Oil Analysis-User Interpretation Guide, CIMAC No. 30/2011

- A Guide to Spectroscopy for used Oil Analysis, Amtek Spectro Scientific, 06/2016

- Parker Kittiwake Analex Brochure

- Oil Analysis User Guide, Agat Labs Ltd.

About the author:

Sanjiv Wazir is a Technical Adviser with LUKOIL Marine Lubricants. He is a mechanical engineer from IIT-Bombay. He is a marine engineer and a member of the Institute of Marine Engineers. He is a Certified Lubrication Specialist from the Society of Tribologists & Lubrication Engineers (STLE), USA and is a member of the Tribological Society of India. He has contributed to MER on marine lubrication developments in the past, and on oil contamination issues under “Lube Matters”, earlier.

He can be reached at sanjiv@lukoil.com